Preparing a 3D model of a product for plastic injection molding

13 February, 2026In modern industrial manufacturing, plastic injection molding is the core technology for mass-producing items, particularly when it comes to wholesale plastic packaging. However, even the most expensive mold does not guarantee a high-quality result if the initial 3D model preparation was done incorrectly. It is the 3D product model for the mold that determines the cost, process stability, and tool longevity. For B2B clients, it is essential to understand the requirements for a 3D model for plastic molding to avoid reworks and delays in mass production launches.

Why is 3D model preparation for plastic molding critical?

In practice, a significant portion of projects requires modifications before the production stage. The reason is simple: a designer's model often fails to account for the actual requirements for injection molding. That is why 3D model preparation for plastic molding is not just cosmetic editing, but an engineering adaptation. It accounts for material shrinkage, ejection directions, injection mold operation, and overall manufacturability. If these factors are ignored, it becomes clear why a 3D model is unsuitable for molding, even if it looks perfect on the screen.

Requirements for 3D product models in injection molding

For a 3D part model to be production-ready, it must meet strict engineering criteria. At this stage, a 3D model analysis for molding is conducted to identify potential risks before the mold is even manufactured. Additionally, 3D model adaptation for molding is performed, where the design is adjusted to account for the actual technological limitations of the equipment and materials.

Key requirements for a 3D product model:

- Uniform wall thickness to prevent sink marks and deformations.

- Properly defined fillet radii to reduce material stress.

- Expertly designed ribs to increase strength without wasting plastic.

- Correct part geometry adapted for easy ejection from the mold (draft angles).

Compliance with these principles directly affects the stability of mass production and the tool's lifespan, especially regarding high volumes and long-term mold operation. A properly prepared model reduces the load on the mold, prevents premature wear, and lowers the risk of defects at the start of the series. As a result, the manufacturer achieves a predictable technological process, high-quality plastic containers from the manufacturer, and optimized production costs.

Most common mistakes in 3D models for injection molds

Even experienced designers sometimes make typical miscalculations. This is why verifying the 3D model before mold manufacturing is a mandatory step. The most common mistakes in 3D models for molds involve uneven wall thickness, sharp corners, or complex geometry that is impossible to replicate in a mold. In such cases, it becomes obvious what needs to be changed in the 3D model before molding to avoid defects, cracks, or part ejection issues.

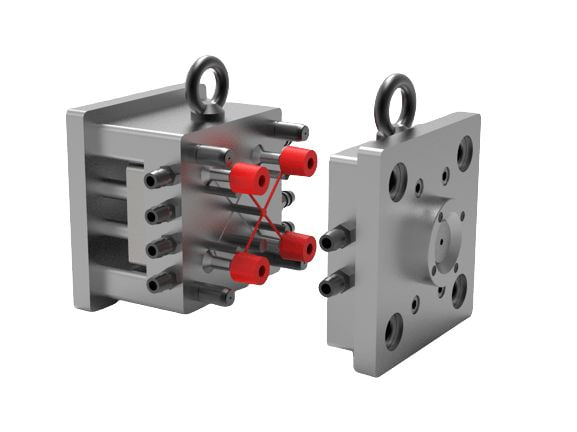

Analysis and model preparation for injection molding from the manufacturer

Professional CAD model preparation for injection molding always starts with deep analysis. How is a 3D model checked before mold production? Engineers evaluate melt flow, material shrinkage, and the placement of gates and ejectors. Such 3D model preparation from the manufacturer minimizes risks and shortens the series launch time. For clients ordering turnkey mold manufacturing, this means a predictable result and quality control at all stages.

3D model as the foundation for mass production of plastic packaging

For companies in the B2B segment, a 3D model for injection molding is the foundation for scaling production. It determines how efficiently wholesale plastic packaging can be manufactured by optimizing materials and the molding cycle. Partnering with a specialist like a plastic packaging manufacturer allows you not only to adapt the model but also to immediately account for real production constraints. This is why, when launching new projects, clients choose plastic buckets from the manufacturer or other plastic products, receiving a solution ready for mass production.

Why a high-quality 3D model is the key to successful molding

In conclusion, it can be said with confidence: preparing a model for injection molding is a critical stage that directly impacts cost, quality, and production stability. A well-executed 3D model analysis before mold manufacturing avoids typical errors and ensures high manufacturability. A similar approach applies to small items, such as plastic cups from the manufacturer, where even minor geometric errors can affect series stability. For business, this means a predictable result, minimal risks, and efficient mass production.

Planning mass production of plastic products or launching a new project? The "Plast Mould" team will help you perform professional preparation and analysis of your 3D model, adapt the design for plastic injection molding, and provide turnkey mold manufacturing. Contact a manufacturer that works with technology rather than fixing mistakes during the production stage.